Easily extend the life of your equipment and lubricant by making a few modifications to your lubrication program.

Case study on a cooling tower fan gearbox failure caused by reduced sampling frequency and trend analysis, which contributed to a lack of maintenance action. This resulted in an $800,000 gearbox failure.

Filtration Systems are a relatively simple and effective way to control contaminants. But choosing the right filtration system for your application is not that easy. There are hundreds of products to choose from, so where do you start? Self-explore the systems with an interactive tool.

Learn how to obtain a multilayered oil sample from 55-gallon drums using a hand-held vacuum pump or a pipette style sampling tube.

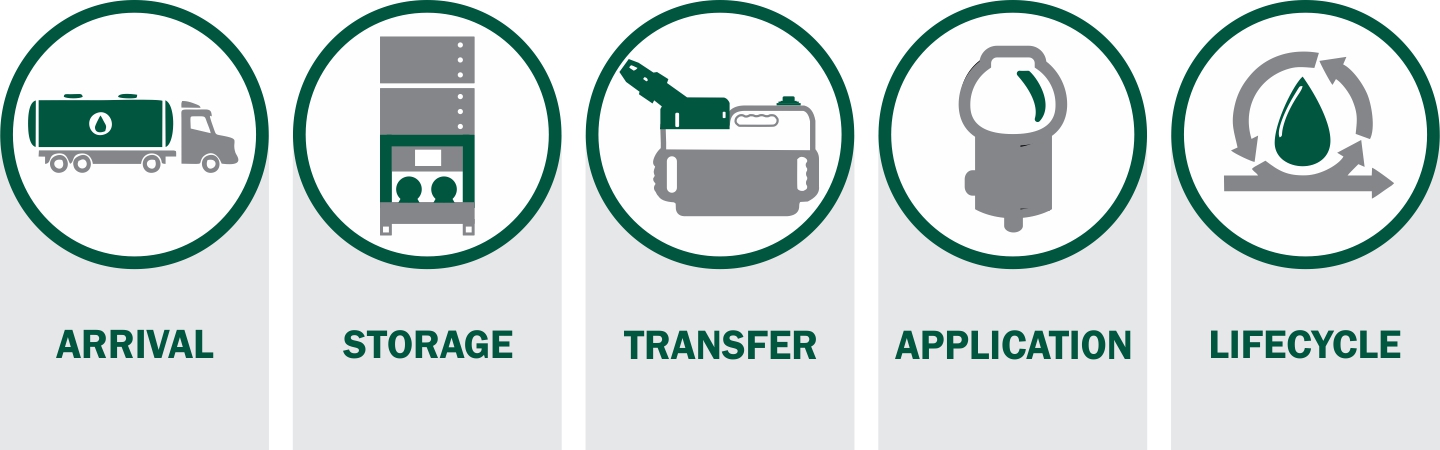

The Journey of the Lubricant® is a series of stages, segregating your lubricant management program into 5 sequential steps during your lubricant's life on-site. Within these stages, dimensional sampling and oil analysis is key to maintaining the health of your lubricant.

Improper lubricant storage and handling can lead to contamination, safety threats and other problems with your lubricating oil. Transform your entire lubrication program by implementing best practices into your lube room with Bulk Oil Storage Systems that protect your lubricants during storage and handling.

Selecting the right filtration system involves many different factors including particle size of contaminants, operating conditions of the system, and lubricant viscosity to name a few. As you research filtration systems, it’s important to consider all your options and taking your time in making the decision as it is an important component in reducing contaminants in your lubricant.

Root cause analysis is a powerful tool for investigating equipment problems when combined with oil analysis. It helps to identify what happened, why it happened, and what can be done to prevent it from happening again.

It is sometimes difficult to decide which test method should be used to determine water content in lubricating oils. Whichever method is used, one thing is certain – water is one of the major causes of lubricant, component, and machine failure.

Using Oil Intelligence to follow the lubricant's journey from arrival through its life cycle, you can see how every step offers an opportunity to implement practices that mitigate risks.